First Place, July 2019, West Kentucky NRHS Photo Contest – CSX locomotive # 958 pulls an intermodal south on the Henderson Subdivision after emerging from the south portal of Ridgetop Tunnel, north of Baker Station crossing in Ridgetop Tennessee on May 30, 2019. – Photo by Bill Farrell.

Second Place, July 2019, West Kentucky NRHS Photo Contest – CSX locomotive # 958 pulls an intermodal south on the Henderson Subdivision after emerging from the south portal of Ridgetop Tunnel, north of Baker Station crossing in Ridgetop Tennessee on May 30, 2019. – Photo by Bill Farrell.

Third Place, July 2019, West Kentucky NRHS Photo Contest – Illinois Central 1026 and 1000 lead a northbound CN mixed freight on the Centralia Subdivision at Champaign, Illinois on July 29, 2019. – Photo by Rick Bivins

Honorable Mention, July 2019, West Kentucky NRHS Photo Contest – BNSF 665 Santa Fe War Bonnet with no patches makes its way south on the Thayer Subdivision on July 5th, 2019 at Mammoth Spring, Arkansas. It’s a GE Model Dash 9-44 CW Series, Build date 8-9-94. – Photo by Donny Knight

Day: August 22, 2019

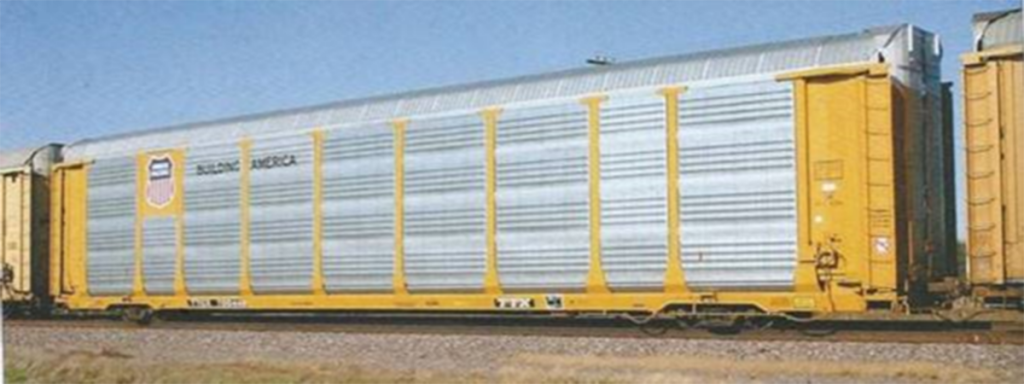

Railroads have long played a major role in the automobile industry, from the era of primitive converted wagons to today’s high-performance cars. Auto manufacturing is a key market segment for railroads, so train schedules have often been geared to production deadlines and needs. There will be at least one follow-up to this series.

The evolution of change in handling finished automobiles is seen here.

Twenty seven loads of “Big Inch” pipe from Kaiser Steel enroute to Wyoming.

So why the boxcars, fore and aft. Those empty cars are for crew protection in the event of a mishap along the way. Those heavy pipes would be like missiles in any kind of sudden stop. The buffer cars provide at least some level of personal protection.

This scene is just north of Sacramento very late in the steam era, September 1956. This Southern Pacific train will deliver the cargo to the Western Pacific at Marysville for onward shipment.

The use of buffer cars continues to this day. 100 plus car trains of crude oil, likewise lengthy trains of ethanol have buffer cars behind the power, you no longer see a caboose and the friendly wave from the crew. Buffer cars today are partially filled with sand to reduce the impact in the event of an accident.

The jury is still out as to the wisdom, efficiency, even the safety of shipping crude via rail or pipeline. My take is in favor of the rails, as the infrastructure allows flexibility in sources and destinations, on an existing transportation plant. No need to tear up the countryside and abuse the environment with underground pipe. Ethanol cannot be shipped via pipeline, so we’ll always that on the rails of barges.

Credits: photos by Richard E. Lohse as seen in Classic Trains – Spring 2018 Gary O. Ostlund

As of July 8, employees have begun light locomotive repairs and inspections.

Citing a rebounding rail industry and an increase in work orders, NRE reopened its 450,000 square foot Paducah, Kentucky plant on July 8, 2019. Employees have begun making light repairs and inspections of locomotives, as well as provide other service offerings.

“We are very excited to be able to reopen the Paducah plant,” said Steven Beal, President of NRE. “The Paducah plant and its employees have a nearly 100 year history of providing quality locomotive products and services. Our goal since we shuttered it two years ago has always been to bring it back online and to get our employees back to work,” he added.

NRE is actively seeking applicants to fill available positions at the plant as the plant increases its operations. If interested, please visit www.nre.com/careers.

When full-strength, NRE Paducah provides the following services:

• New Locomotive Builds

• Remanufactured Locomotives

• Locomotive Service

• Field Service

• New Parts and Components

• Remanufactured Parts and Components

• Salvage

“The reopening of the Paducah facility is merely the beginning,” said Beal. “Paducah will be a key component of the future of our company and we look forward to growing together.”

For more information, please contact Brandon Schwartz at 618.899.5591 or b.schwartz@nre.com. – Submitted by Chris Dees

Mishaps will always be a part of railroading. These scenes show the old and newer methods of cleaning up a wreck scene. In years past the railroads owned and positioned “big hooks” and associated equipment out on the line. Such equipment was always in the ready-mode, warmed up and on the go in a moment’s notice.

In today’s “contract-out” way of doing business, private firms like Hulcher Services are called to the task. They and other firms have highway transportable lifting equipment on the scene dispatched from numerous locations around the country. Upon completion of the Interstate highway system truck-transported clean-up equipment allowed the rail lines to reopen sooner.

Note the special tread on the pair of crawler tractor side-mounted lifting machines. I didn’t use the word “Caterpillar” because their origin could be of a different manufacturer.